Insulating Glass (TENON)

Tempering Furnace

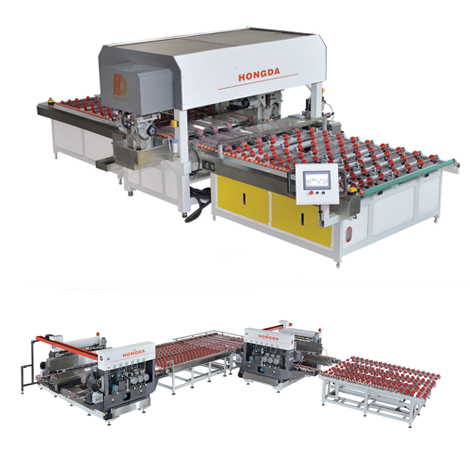

All types of Glass Washing machines

TECHWIN is a 100% dedicated manufacturer specialized in washing machines. It has built for itself a GOLDEN name among Glass machinery manufacturers association in China.

Besides supplying for the glass processors all their needs of washers (vertical, horizontal, high speed, or economic), TECHWIN is also a prime supplier for other machinery manufacturers who need washers for their lines (insulating glass machines, laminating lines, tempering…)

We can supply you any type of washers, even for touch screen processing. We are proud to introduce our high grade C- Type washer that is built from aluminum and can reach speed of 15 m/min

TECHWIN means washing

Washing means TECHWIN

Double Edging and Seaming machines

Edging ,bevelling and drilling

Glass Hardware Accessories

Vacuum Lifters

Bending and Fusing Furnaces

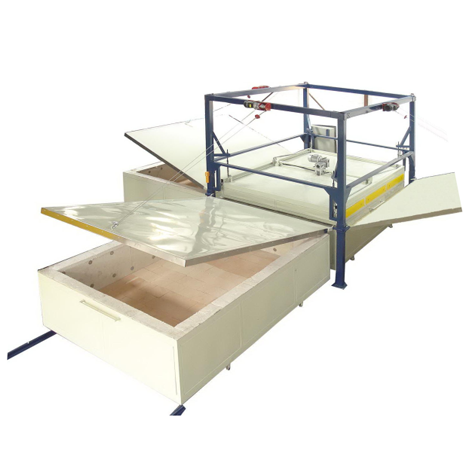

Laminating Furnaces

Automated Solutions

Vacuum Process for windshields

Sand blasting macines

Denver

PRODUCT SUPPORT

All of our customers can feel 100% confident when buying water filtration products from us because we offer the best product support and after sales services in the business, and we’ve got the testimonials to prove it. No matter what your questions or queries, our experts are just a phone call away and will be more than happy to guide you through the process or answer any of your queries. So, if you are still on the fence when it comes to getting a water treatment product, just give us a call and we’ll clear it up for you.

Advanced Glass

Advanced Glass